MB Fiber ltd. was born in 1990 in 400 square meters, by the will of a passionate and highly motivated family.

A 4 people company, with 6 moulding machines, and the cutting of the shells was entirely hand-built.

Today the whole production occupies an area of 1,200 square meters. Spaces are clean and controlled. Our professional staff provides excellent quality of the product, from raw materials to delivery.

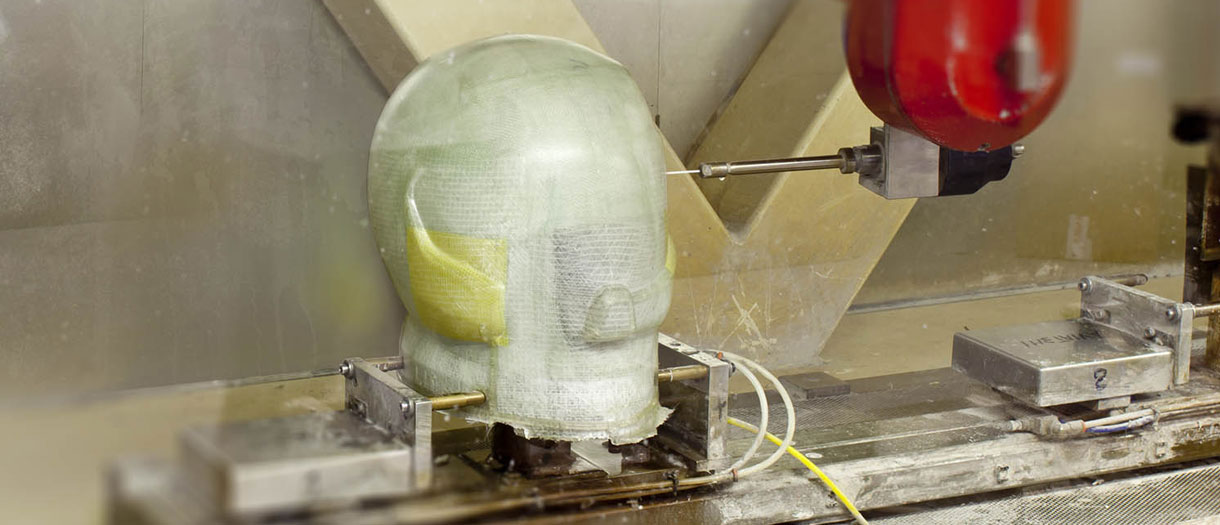

Our today's numbers are: 23 machines, 2 cutting centers and 15 employees working in high-tech workstations. Everything’s under computer control where each product takes shape by our competence and great proficiency.